Roll forming represents one of the most efficient continuous metal forming processes in modern manufacturing. Understanding the technical specifications and process steps is crucial for achieving optimal production outcomes. This article examines the 7 critical steps in the roll forming process and the key technical specifications that ensure maximum efficiency and precision.

The 7 Essential Steps in the Roll Forming Process

1. Material Preparation and Coil Loading

The process begins with proper material preparation. Modern decoilers handle universal coil sizes weighing up to 3300-6500 lbs, with guided in-feed systems that center the coil and reduce stress on rollers. 1 The leading edge is precisely trimmed to ensure smooth feeding into pre-press machinery, minimizing startup scrap and improving efficiency in high-volume operations.

2. Flattening and Leveling

Before entering the roll forming machine, the material strip undergoes flattening to remove coil set and ensure dimensional consistency. This critical step prevents jams, misfeeds, and dimensional inconsistencies in the final product. Proper leveling is essential for materials with thickness variations between 0.69-1.2 mm, which are common in many industrial applications.

3. Pre-Punching Operations

Many modern roll forming lines incorporate pre-punching operations to create holes, slots, and other features before the material enters the forming rolls. This integration streamlines manufacturing by reducing the need for secondary machining and ensures features are precisely located prior to forming. The press feed unit guides the strip to ensure smooth entry into either the pre-punch press or directly into the roll forming machine.

4. Progressive Roll Forming

The core of the process involves passing the material through multiple roller stations that gradually shape it into the desired profile. Advanced systems utilize 7-13 roller stations to form profiles with depths ranging from 63-140 mm. Each station applies incremental bends, typically with a 0.030″ diameter step-up between passes to prevent overfeeding and ensure smooth material flow. This multi-stage approach ensures smoother finishes, tighter tolerances, and reduced roll wear.

5. In-line Secondary Operations

Modern roll forming machines incorporate in-line secondary operations such as notching, dimpling, and flattening. Notching removes specific areas of the profile to accommodate joints or service penetrations. Dimpling creates small indentations for screw heads or structural reinforcement. Flattening improves fit and prepares parts for fastening. These operations are performed by dedicated toolsets within the machine and can be fully automated.

6. Precision Cutting

The continuous formed profile is cut to precise lengths using integrated guillotine or flying cut-off systems. Advanced machines use closed-loop servo systems that track tooling to within 0.0001″-0.0002″ (0.00254-0.00508 mm), allowing for extremely accurate positioning without interrupting production flow. Ball screw actuators driven by rotary servo motors provide tight mechanical coupling for precise cut-off operations.

7. Quality Control and Material Handling

The final step involves quality inspection and efficient handling of finished products. This includes measuring devices like micrometers, calipers, and gauges to verify specifications, as well as systems for efficient stacking and bundling of finished pieces. Proper quality control ensures adherence to dimensional tolerances and surface finish requirements.

Key Technical Specifications of Modern Roll Forming Machines

Production Efficiency Metrics

Modern roll forming machines deliver impressive production output—up to 18,000 pieces per shift—making them ideal for high-volume manufacturing. Their continuous operation capability allows for 24/7 production with minimal downtime, significantly enhancing manufacturing efficiency.

Material Compatibility and Dimensions

Roll forming machines can process a wide range of materials, including mild steel, aluminum, copper, and brass. 7Standard machines are available in widths of 50mm, 75mm, 100mm, 120mm, with custom widths available for specific applications. Material thickness typically ranges from 0.69mm to 1.2mm for structural applications.

Control Systems and Automation

Modern roll forming machines feature computerized control systems that allow operators to set and adjust parameters such as roll positions, line speed, and material feed. Many are compatible with design software like Vertex BD, Strucsoft MWF, and Framebuilder, enabling a streamlined design-to-production pipeline. This integration reduces setup time dramatically, optimizing operational efficiency and minimizing downtime.

Advantages of Advanced Roll Forming Technology

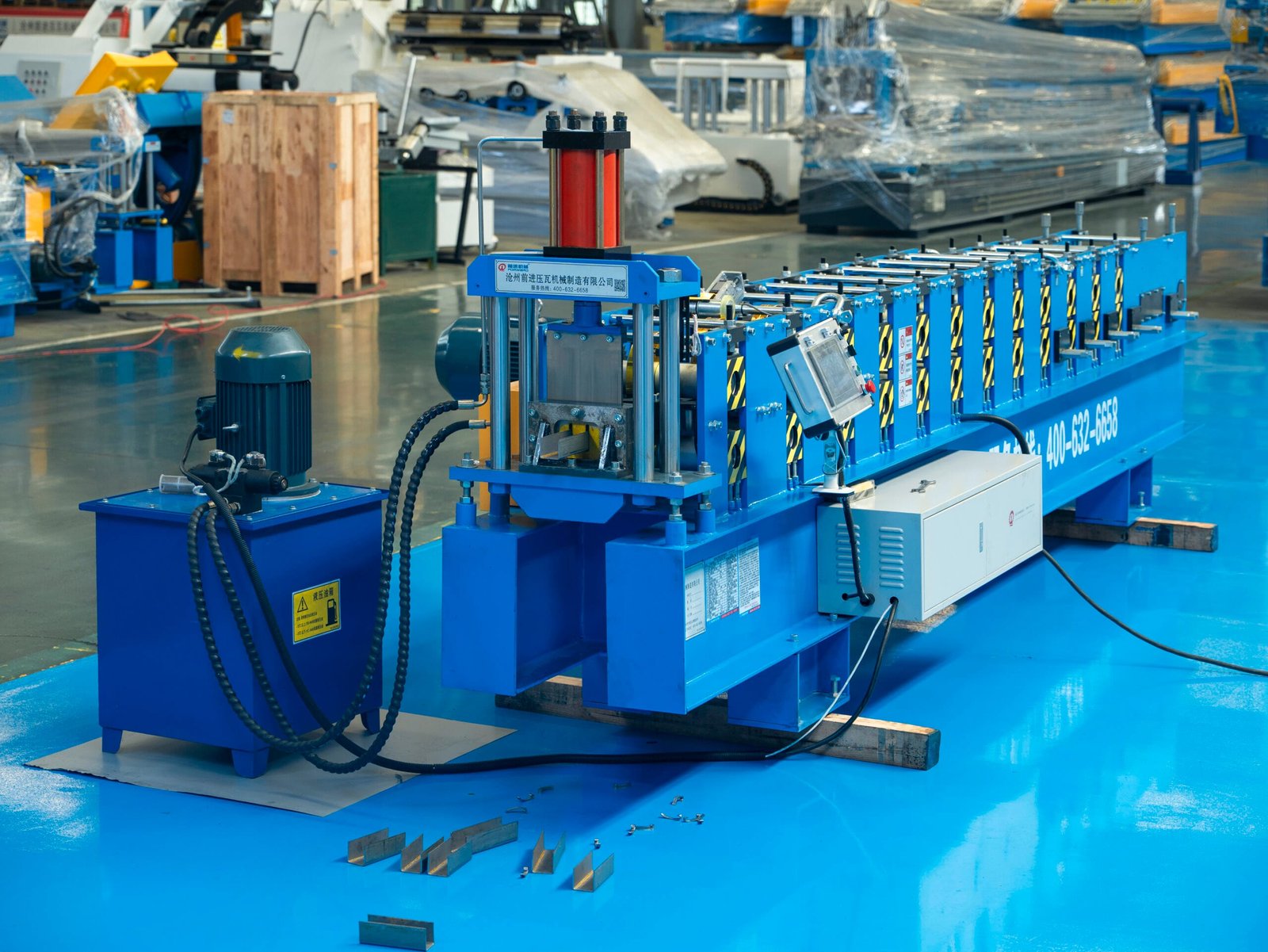

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd has been at the forefront of roll forming technology since 2008, specializing in cold roll forming equipment and automatic production lines. Their machines incorporate all seven critical process steps with precision engineering and advanced control systems.

The company’s roll forming solutions offer several key advantages:

- Flexibility – Ability to produce unlimited profiles by simply changing roller dies

- Efficiency – High production output with continuous operation capability

- Space Efficiency – Compact footprint saves valuable factory floor space

- Versatility – Ability to process various materials and thicknesses

- Scalability – Output easily increased by running additional shifts

- Productivity – Continuous production with minimal downtime

- Durability – Robust machines built for 24/7 operation

Conclusion

The 7-step roll forming process represents a highly efficient and precise metal forming method that delivers consistent, complex profiles from sheet metal. By understanding the technical specifications and process steps outlined in this article, manufacturers can optimize their roll forming operations for maximum efficiency and quality.

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd continues to innovate in roll forming technology, offering state-of-the-art machines that incorporate these seven critical steps with precision engineering and advanced control systems. Their CE, SGS, BV, and ISO9001 certified equipment ensures manufacturers can achieve the highest standards of quality and efficiency in metal forming operations.