Discover how to evaluate roll forming machine manufacturers based on technical strengths, product range, and real-world applications to make the right investment.

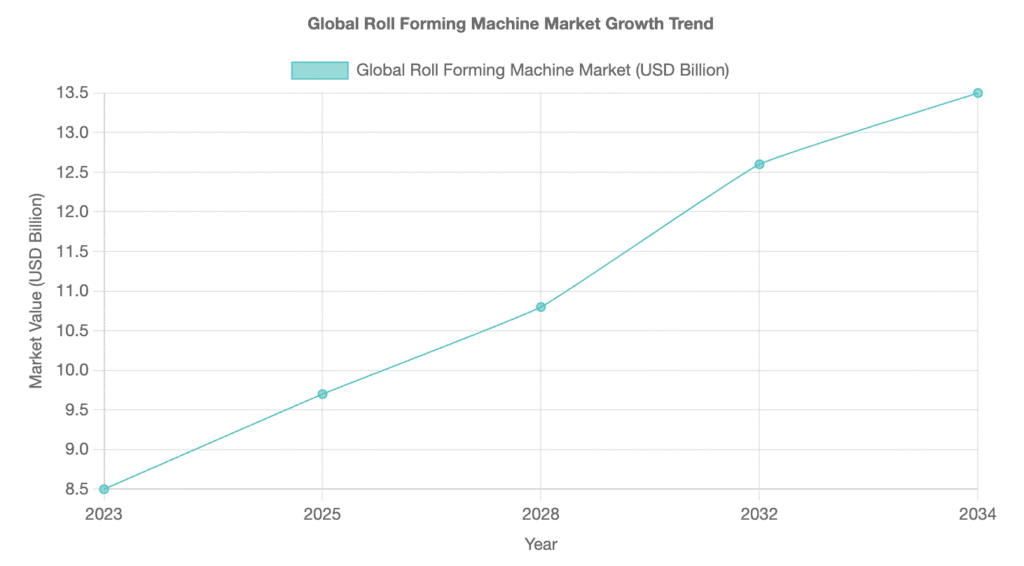

In today’s competitive manufacturing landscape, the demand for precision, efficiency, and cost-effectiveness in metal shaping is paramount. Choosing the right equipment, particularly a high-quality roll forming machine, can be a game-changer for businesses across various industries. These machines offer a sophisticated method for continuously bending long strips of sheet metal into desired cross-sections, critical for modern metal fabrication.

This comprehensive guide aims to delve deep into the world of roll forming machine technology. We will explore its fundamental principles, uncover its significant technical advantages, showcase its diverse applications, and critically, provide you with a roadmap for selecting a professional and reliable roll forming machine manufacturer. Mastery of roll forming technology is essential for any enterprise aiming for top-tier precision engineering in their metal products.

As specialists in cold roll forming equipment and automated production lines, Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd understands the intricacies involved in this technology and the critical factors that lead to successful implementation. This article draws upon industry knowledge and experience to empower you in making an informed decision.

What is a Roll Forming Machine?

A roll forming machine is a specialized piece of industrial equipment designed to shape flat metal sheets or strips into specific, uniform profiles through a continuous bending process. The metal strip is fed through a series of rotating rollers (or roll stands), with each set of rollers incrementally forming the metal until the desired cross-section is achieved. This process is typically performed at room temperature, often referred to as cold roll forming. This technique is central to efficient sheet metal processing, producing precise metal profiles.

The key components of a roll forming machine line generally include an uncoiler (to hold and feed the metal coil), an entry guide, the forming mill (series of roll stands), a cutting mechanism (to cut the formed profile to length), and a run-out table. Advanced lines, such as those developed by Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd, often integrate pre-punching, pre-notching, in-line welding, and other operations to produce finished or near-finished parts within a single automated process. This integration significantly enhances efficiency, especially in automated production lines, which are a hallmark of modern industrial machinery. The entire roll forming process is engineered for consistency and speed.

Core Technical Advantages of Roll Forming Machines

The adoption of roll forming machines offers a multitude of technical benefits that translate into superior products and improved manufacturing economics. These roll forming advantages are pivotal for companies aiming for leadership in their respective markets.

High Precision and Consistency

Roll forming excels at producing parts with exceptional dimensional accuracy and uniformity over long production runs. Each roller station is precisely engineered to impart a specific bend, ensuring that every piece produced adheres to the same specifications, minimizing variations and defects. The progressive nature of the forming reduces stress on the material compared to other methods. This capability is fundamental to precision metal forming.

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd leverages advanced CAD/CAM software for roll tooling design and precision machining of rollers, coupled with robust machine frames, to ensure high-precision roll forming outputs for complex profiles.

Enhanced Production Efficiency and Speed

Roll forming is a high-speed process ideal for high-volume production. Once set up, the machine operates continuously, feeding, forming, and often cutting parts automatically with minimal human intervention. Production speeds can range significantly, depending on profile complexity and material, often much faster than press braking or stamping for long parts. This efficiency translates directly to lower lead times and higher throughput, crucial for meeting demanding production schedules.

Cost-Effectiveness (Material Utilization, Energy Savings, Reduced Labor)

One of the most significant roll forming advantages is overall reduced manufacturing costs through several avenues:

- Material Utilization: Roll forming is highly material-efficient, typically resulting in scrap rates as low as 1-3% (SPE Automotive mentions 3-5% vs 15-20% for stamping). This material efficiency is because forming is continuous and often uses coil stock precisely suited to the part width.

- Energy Savings: Being a cold roll forming process, it doesn’t require heating the metal, which saves considerable energy compared to hot forming or extrusion.

- Reduced Labor: The high degree of automation in modern roll forming machine lines, especially automated production lines, reduces the need for manual labor, lowering operational costs.

Versatility and Design Flexibility

- Complex Profiles: Roll forming can produce a vast array of simple to highly custom metal profiles and complex cross-sectional profiles that would be difficult or impossible to achieve cost-effectively with other methods. It allows for intricate designs, including multiple bends, varying thicknesses within a profile (with specialized tooling), and the creation of both open and closed (welded) sections.

- Variety of Materials: The process is suitable for a wide range of ferrous and non-ferrous metals, including steel (carbon, stainless, galvanized, pre-painted), aluminum, copper, and brass (IQS Directory – Roll Forming Materials).

Improved Structural Strength

The cold working of the metal during the roll forming process can lead to strain hardening, which can increase the yield and tensile strength of the finished part (Drawn Metal – Cold Rolling Benefits). This allows for the use of lighter gauge materials without sacrificing structural integrity, a key factor in advanced manufacturing.

Integration of In-Line Secondary Processes

Modern roll forming machine lines can integrate various secondary operations such as hole punching, notching, slotting, embossing, shearing, welding, and even light assembly (Dallan – In-line Processes). This in-line processing produces a more complete part directly off the machine, eliminating the need for separate downstream operations, saving time, handling, and cost. Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd specializes in designing such integrated automated production lines.

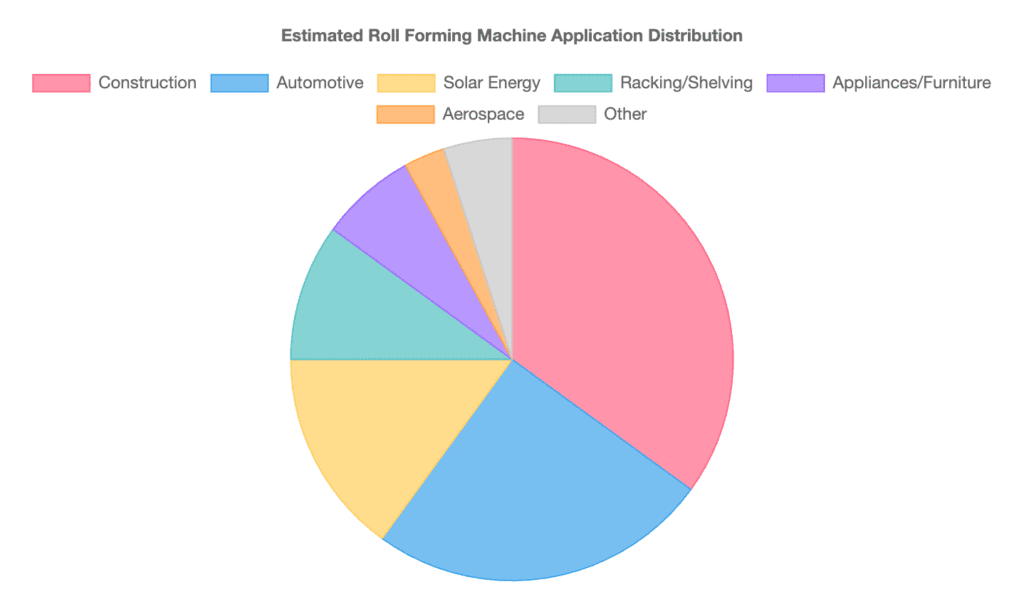

Wide Applications of Roll Forming Machines

The versatility and efficiency of roll forming machine teknolojisi have led to its adoption across a multitude of industries. The scope of roll forming applications is continually expanding.

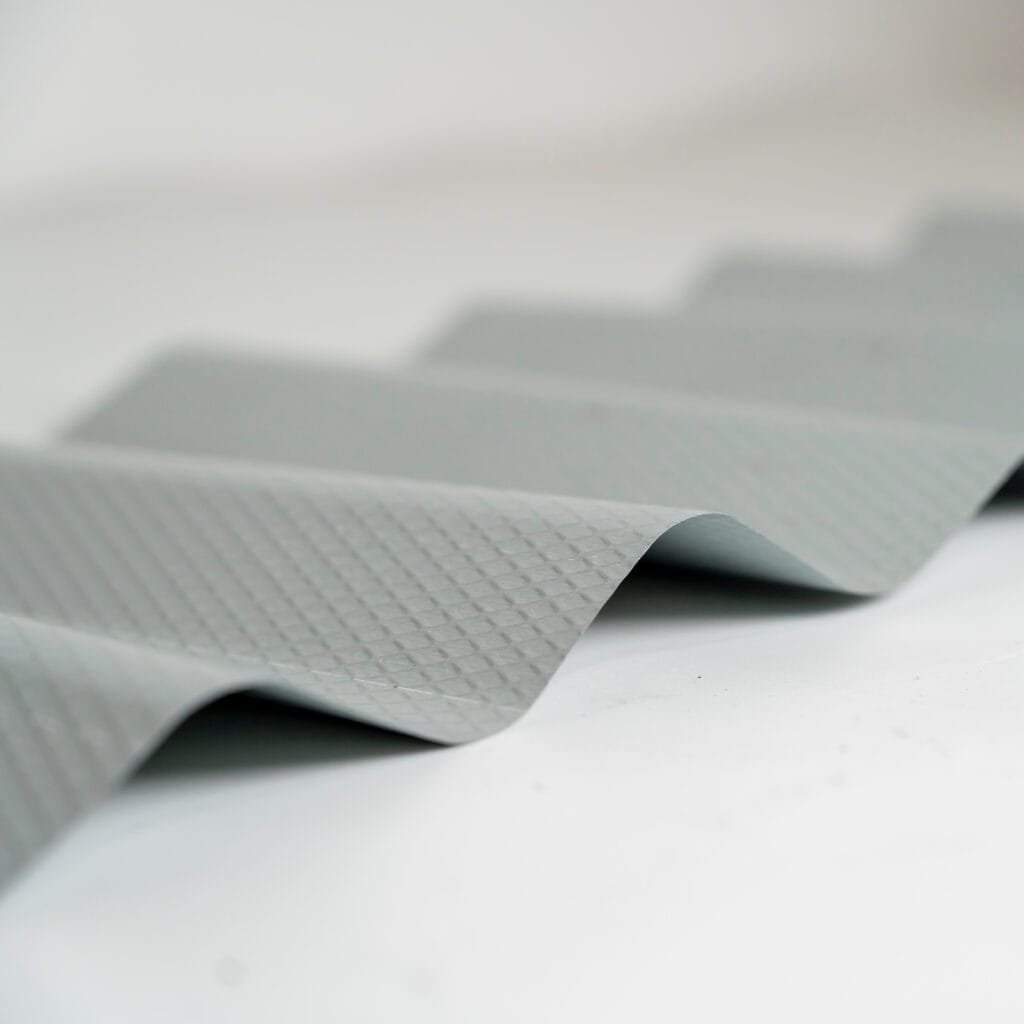

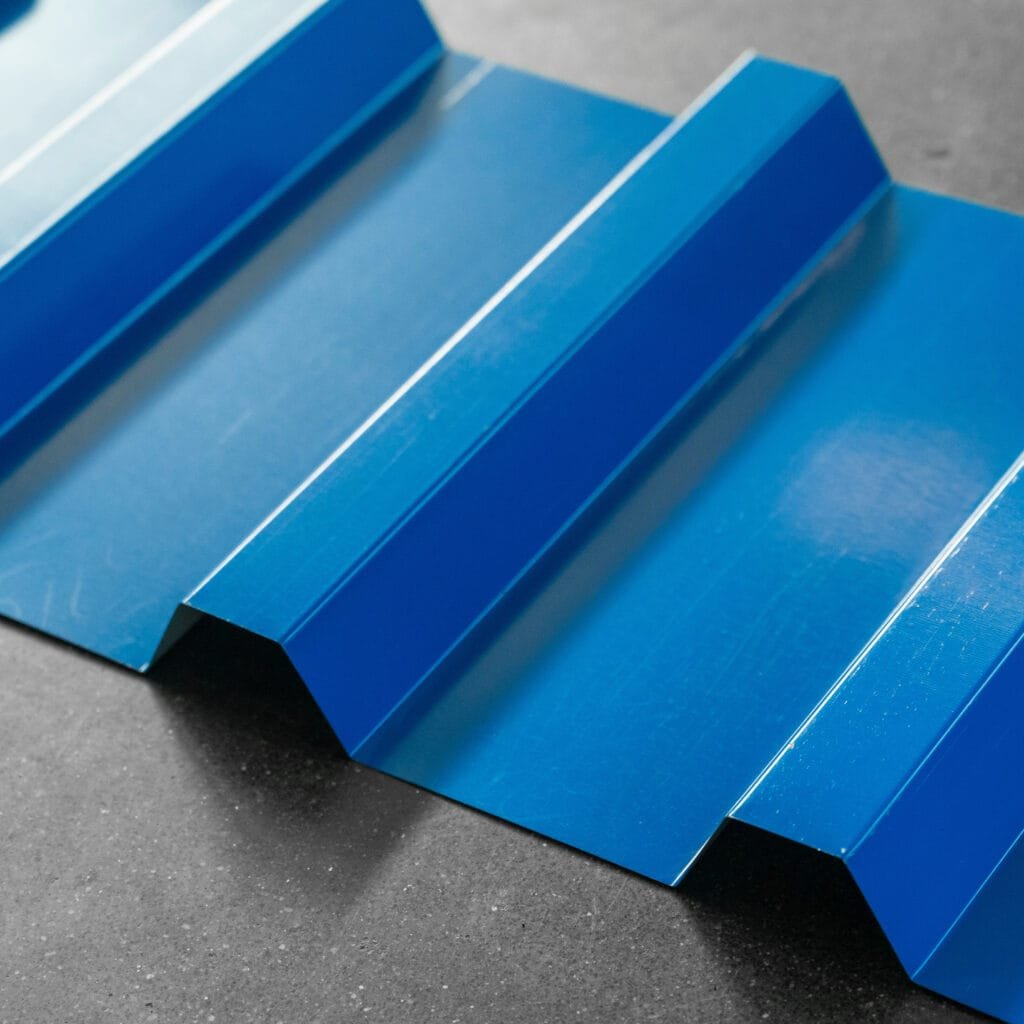

Construction and Building Materials

This is one of the largest application areas. Roll formed products include structural building components like C&Z purlins, studs and tracks for light steel framing systems, roofing panels (e.g., standing seam, corrugated), wall panels, cladding, gutters, downpipes, door and window frames, and highway guardrails (Machine Matcher – Guardrails). The ability to produce long, consistent lengths is a major advantage here. For insights into material trends, one might consult Construction Dive for articles on steel in construction.

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd provides robust machines for producing a wide range of construction profiles, designed for durability and high output.

Automotive Industry

Roll forming is extensively used for manufacturing various automotive components, including structural parts (chassis members, A/B/C pillars, reinforcements), door impact beams, seat tracks, decorative trim, bumpers, and increasingly, components for Electric Vehicles (EVs) such as battery tray components and structural supports. The Fabricator often covers roll forming in EV manufacturing. The demand for lightweight, high-strength steel (HSS) and Advanced High-Strength Steel (AHSS) parts in automotive parts manufacturing to improve fuel efficiency and safety makes roll forming an ideal choice.

Renewable Energy Sector (Solar)

The solar industry relies heavily on roll formed components for photovoltaic (PV) mounting systems. This includes frames for solar panels, support rails, ground posts, and tracking system components for solar panel racking. Precision, durability, and cost-effectiveness are key (Dahlstrom Roll Form – Solar Applications). For updates on solar technology, Solar Power World is a good resource.

Cangzhou Forward can offer specialized lines for producing these intricate solar racking profiles.

Appliances and Furniture

Components for appliances like refrigerators, ovens, and washing machines (e.g., drawers, shelves, frames, panels) and metal furniture (e.g., shelving units, office furniture frames, cabinet rails) are often roll formed. This highlights the adaptability of metal profile manufacturing.

Racking and Shelving Systems

Warehouse racking, industrial shelving solutions, and retail display units utilize numerous roll formed profiles like uprights, beams, and shelf supports. The ability to punch slots and holes in-line is particularly beneficial for these applications.

Aerospace

While more specialized, roll forming is used for certain aerospace components where lightweight, high-strength profiles are needed, such as stringers and frames (Metmac – Aerospace Components).

Other Applications

Conveyor systems, HVAC ductwork, electrical enclosures, agricultural equipment, and many other industrial and commercial products leverage roll formed parts. The versatility of a steel forming machine makes it invaluable across sectors.

Key Factors for Choosing a Professional Roll Forming Machine Manufacturer

Selecting the right roll forming machine manufacturer or roll forming machine supplier is a critical business decision that can significantly impact your production quality, efficiency, and long-term ROI. Due diligence is essential.

Technical Expertise and R&D Capabilities

Look for a manufacturer with a deep understanding of roll forming theory, tooling design, and material behavior. Evidence of R&D, innovation (e.g., patents, integration of new technologies like AI or advanced sensors), and a strong engineering team are good indicators. Ask about their experience with your specific material and profile complexity. Cangzhou Forward invests in continuous improvement of its cold roll forming equipment designs. Some manufacturers like Zheng Liming highlight their patent portfolios (96 patents including 18 inventions).

Manufacturing Process and Quality Control

Inquire about their manufacturing standards, the quality of materials used for machine components (especially rollers and shafts), and their quality assurance in manufacturing systems (e.g., ISO certifications). Precision machining capabilities for tooling are paramount.

Customization Capabilities and Solution-Oriented Approach

A good manufacturer should be able to offer custom roll forming solutions tailored to your specific product requirements, production volume, and level of automation. This is particularly important for automated production lines. They should work as a partner to design the optimal line configuration, not just sell a standard machine.

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd prides itself on developing bespoke automated production lines to meet unique client needs.

Industry Experience and Proven Track Record

Choose a manufacturer with demonstrable experience in your industry or with similar applications. Ask for case studies, customer testimonials, or references. A long history often indicates stability and expertise. For example, Patech Forming lists several established manufacturers with long histories.

After-Sales Service and Technical Support

Reliable after-sales service, including installation, training, readily available spare parts, and prompt technical support and service, is crucial for minimizing downtime and ensuring the longevity of your investment.

Understanding of Modern Technologies

Manufacturers who are incorporating or have expertise in integrating smart technologies (e.g., CNC controls, servo drives, sensors for process monitoring, readiness for Industry 4.0 concepts) are often more future-proof. This aligns with the trend towards smart manufacturing.

The Future of Roll Forming Technology

The roll forming industry is continually evolving, driven by the need for greater efficiency, precision, and flexibility. Key trends shaping the future include:

- Increased Automation and Smart Factories: Integration of robotics, AI in roll forming for process control, predictive maintenance using IIoT sensors, and digital twin technology for simulation and optimization (Super Rollforming – Emerging Technologies). This leads to „smarter“ automated production lines. McKinsey often discusses Industry 4.0 in metal fabrication and manufacturing.

- Advanced Materials: Growing use of HSS, AHSS, aluminum alloys, and even composites, requiring more sophisticated machine designs and tooling for advanced steel forming to handle their unique forming characteristics.

- Flexible Roll Forming (3D Roll Forming): Technology that allows for the production of profiles with varying cross-sections along their length, opening up new design possibilities, especially in the automotive sector (ScienceDirect – 3D roll forming automotive).

- Sustainability: Focus on energy-efficient machine designs and processes that minimize material waste, aligning with global green sustainable manufacturing initiatives.

Manufacturers like Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd are actively monitoring and adopting these advancements to provide cutting-edge cold roll forming equipment.

Why Choose Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd for Your Roll Forming Machine Needs

With years of dedicated experience, Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd has established itself as a leading specialist in cold roll forming equipment and the design of comprehensive automated production lines. Our core competencies lie in translating complex customer requirements into efficient, reliable, and high-performance Cangzhou Forward roll forming machine an expert roll forming solutions.

We excel in:

- Custom Design and Engineering: Our strong engineering team utilizes advanced design software to create bespoke roll tooling and machine configurations tailored to produce your specific profiles with optimal precision and efficiency.

- High-Quality Manufacturing: We adhere to stringent quality control standards throughout our manufacturing process, using high-grade materials for critical machine components to ensure durability and longevity.

- Focus on Automation: We specialize in integrating various in-line processes, from pre-punching and cutting to welding and automatic stacking, creating seamless automated production lines and automated cold forming lines that minimize labor and maximize output.

- Comprehensive Support: From initial consultation and line design to installation, operator training, and ongoing after-sales service, we are committed to our customers‘ success. Learn more about our solutions.

- Proven Expertise: We have a track record of successfully delivering roll forming solutions to diverse industries, understanding the unique challenges and quality demands of each.

Choosing Cangzhou Forward means partnering with a manufacturer committed to innovation, quality, and your specific production goals.

Conclusion

The roll forming machine stands as a cornerstone of modern metal fabrication, offering unparalleled advantages in precision, efficiency, and cost-effectiveness for producing a wide array of metal profiles. Its applications span critical industries, driving innovation and productivity.

However, harnessing the full potential of this technology hinges on selecting a manufacturer that not only provides quality equipment but also offers expertise, customization, and robust support. An invest in roll forming is an investment in future manufacturing capability.

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd, with its specialization in cold roll forming equipment and automated production lines, is poised to be your ideal partner. We invite you to contact us (contact roll forming experts) to discuss your specific requirements and discover how our tailored roll forming solutions can elevate your manufacturing capabilities and help you optimize metal fabrication processes.

Key Takeaways

- Roll forming machines offer high precision, efficiency, and cost savings in metal profile manufacturing.

- Key advantages include superior material utilization, energy savings, reduced labor, design flexibility, and improved structural strength.

- Applications are diverse, spanning construction, automotive, solar energy, appliances, and more.

- Choosing the right roll forming machine manufacturer involves evaluating technical expertise, quality control, customization, industry experience, and after-sales support.

- Future trends point towards increased automation, AI integration, advanced materials, and sustainability.

- Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd is a specialized provider of cold roll forming equipment and automated production lines.