The Fundamental Principles of Roll Forming

Roll forming is a progressive metal forming process that employs a series of precisely aligned roller stations to achieve incremental bending on continuously fed metal strips. 1 Each station performs a small part of the entire bending operation, gradually transforming the flat metal into the desired cross-sectional profile.

The process begins with a large coil of sheet metal, which can range from 1 inch to 30 inches wide with a thickness of 0.012 inch to 0.2 inch. 1 Before processing, the metal undergoes several preparatory steps:

- Uncoiling : The metal coil is mounted onto an industrial uncoiler or decoiler machine and passed through a straightener to remove any coil set and ensure optimal flatness.

- Pre-processing : The leading edge is precisely trimmed to allow for smooth and even feeding into the forming rollers.

- Progressive Forming : The metal strip passes through multiple roll stations, each performing a small incremental bend according to a predetermined „flower pattern“ that outlines the progressive alterations to the metal.

- Cutting and Finishing : Once the required shape is achieved, the formed profile is cut to the desired length and may undergo additional finishing processes such as cleaning, anodizing, or detailing.

Key Components of Roll Forming Machines

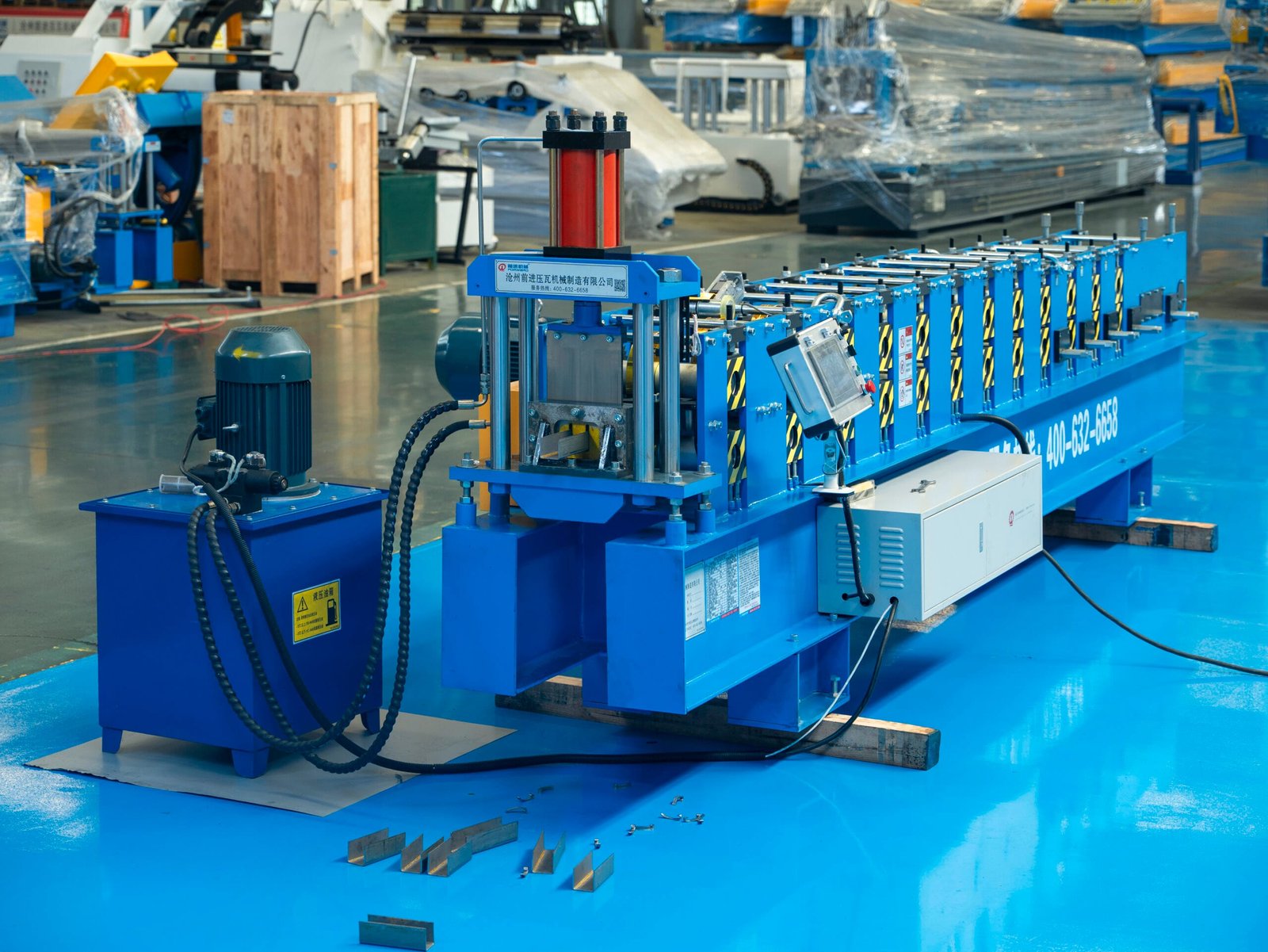

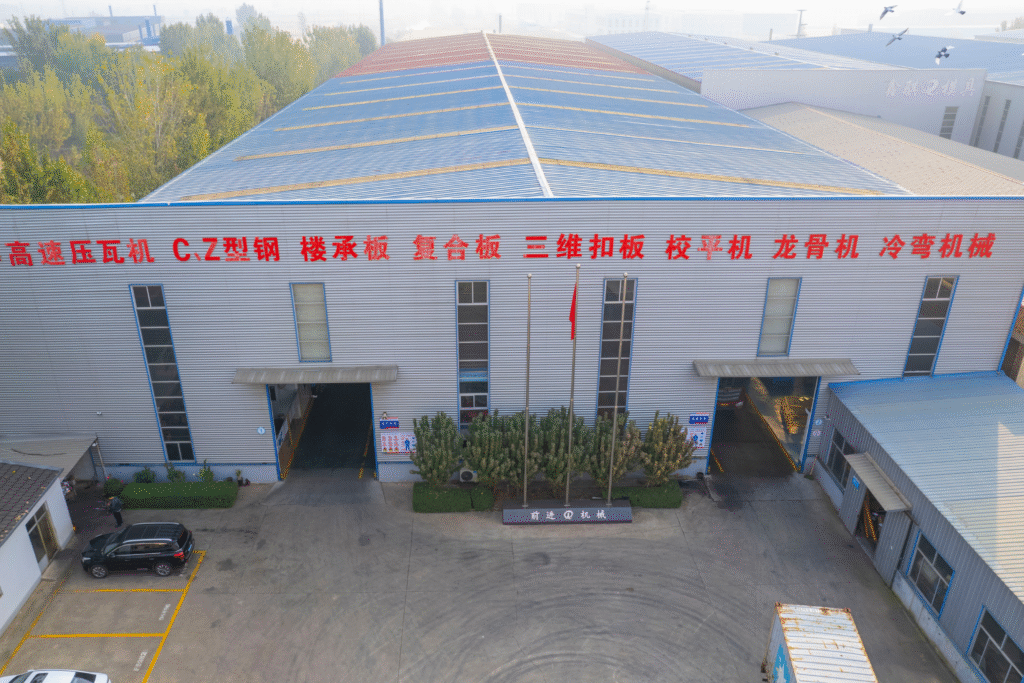

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd designs and manufactures roll forming machines with several essential components that ensure precision, efficiency, and reliability:

- Rolling Stations : The number of rolling stations determines the type of profile that can be produced. These stations form various bends and produce stiffeners along the profile web.

- Decoiler : Automatic decoilers store and unroll steel coils into the roll formers seamlessly, ensuring a constant input of material. Forward’s machines feature decoilers with capacities ranging from 1500 kg to 4500 kg, allowing customers to choose based on their specific needs.

- Hydraulic Systems : These power critical operations such as cutting, notching, and punching. The speed, efficiency, and precision of these operations depend heavily on the performance of the hydraulic system.

- Electrical Systems : Acting as the communication and control hub, electrical systems manage motor drives, sensors, PLCs, and safety devices, ensuring synchronization, precision, and safety during operation.

Technical Advantages of Roll Forming

Roll forming offers numerous technical advantages that make it the preferred method for many manufacturing applications:

- High Production Efficiency : The continuous nature of roll forming allows for high-volume production with minimal downtime, making it ideal for mass production requirements.

- Precision and Uniformity : The multiple roller stations ensure the metal is shaped accurately, resulting in components that meet exact specifications with consistent quality throughout long production runs.

- Material Versatility : Cangzhou Forward Roll Forming Machinery designs machines that can work with various materials, including steel, aluminum, stainless steel, copper, and other metal alloys, providing flexibility for different applications.

- Reduced Secondary Operations : The precision achieved through roll forming often eliminates the need for additional operations such as welding or machining, reducing production time and overall manufacturing costs.

- Material Utilization : The process minimizes material waste since it generates minimal scrap compared to other fabrication methods like stamping or machining.

- Complex Profile Capabilities : Forward’s roll forming machines can produce intricate and complex cross-sectional profiles that would be difficult or impossible to achieve with other forming methods.

Industrial Applications of Roll Forming Technology

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd provides roll forming solutions for various industries and applications:

- Construction Industry : Roll formed products are extensively used in building components such as roof and wall panels, purlins, studs, tracks, and structural framing members.

- Automotive Sector : The automotive industry utilizes roll formed components for bumpers, chassis parts, window frames, and structural reinforcements.

- Industrial Buildings : Forward’s machines produce profiles widely used in factories, warehouses, gymnasiums, and exhibition halls for both roofing and wall systems.

- Solar Mounting Systems : Roll formed rails and brackets are essential components in solar panel mounting structures.

- Storage Systems : Shelving, racking, and storage systems benefit from the strength and precision of roll formed components.

Technological Advancements in Roll Forming

Modern roll forming technology has evolved significantly with the integration of advanced systems:

- CAD/CAM Integration : Computer-aided design and manufacturing systems assist in roll forming, helping machines reach their maximum potential while reducing the need for manual intervention.

- CNC Controls : Programmable logic controllers (PLCs) and computerized numerical control systems enable precise control over the entire roll forming process, ensuring consistent quality and reducing setup times.

- In-Line Operations : Modern roll forming lines can incorporate additional operations such as punching, notching, embossing, and perforating, allowing for complete component fabrication in a single production line.

Conclusion

Roll forming technology continues to evolve as a critical manufacturing process for producing consistent, high-quality metal profiles efficiently. Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd , with its focus on research, development, and manufacturing of cold roll forming equipment and automatic production lines, remains committed to advancing this technology through innovation and quality engineering.

With CE, SGS, BV, and ISO9001 certifications, Forward maintains its position as a leading manufacturer in the industry, providing customized solutions that meet the specific needs of clients across various sectors. As industrial development continues worldwide, the demand for advanced roll forming machinery will continue to grow, making companies like Cangzhou Forward essential partners in modern manufacturing.