Roll Forming Machine Industry Showcases Innovation at Global Exhibitions

The roll forming machine industry continues to evolve rapidly in 2025, with significant technological advancements and market growth being showcased at major international exhibitions. These events provide crucial platforms for manufacturers like Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd to demonstrate their latest innovations and connect with global buyers seeking cutting-edge metal forming solutions.

Key Industry Exhibitions Highlighting Roll Forming Technology

The 2024 exhibition calendar has featured several prominent events dedicated to metal forming technology. The Metal Forming Expo, scheduled for its 4th edition in April 2026 at Pune International Exhibition and Convention Centre (PIECC), continues to be a major showcase for sheet metal working, metal forming, and precision engineering technologies.

IMTEX FORMING 2026, recognized as Asia’s largest metal forming and manufacturing show, will take place from January 21-25 at BIEC, Bengaluru. This exhibition attracts over 44,000 visitors and features more than 625 exhibitors from 20+ countries, making it an essential event for companies like Cangzhou Forward to showcase their expertise in cold roll forming equipment.

In Europe, LAMIERA 2025 will be held from May 6-9 at fieramilano Rho, representing Italy’s exclusive exhibition for sheet metal forming and cutting technologies. With over 400 companies participating in its previous edition, this event has become a critical platform for international market expansion.

Technological Innovations Driving the Industry Forward

The roll forming machine sector is witnessing significant technological advancements, particularly in automation and smart manufacturing. Industry 4.0 technologies, including IoT and AI, are revolutionizing production processes with real-time monitoring systems for predictive maintenance and reduced downtime.

In February 2024, the Engineering Technology Group (ETG) launched a new fabrication division featuring advanced technologies such as tube bending, flatbed laser cutting, and cold roll forming. This development reflects the industry’s move toward comprehensive manufacturing solutions.

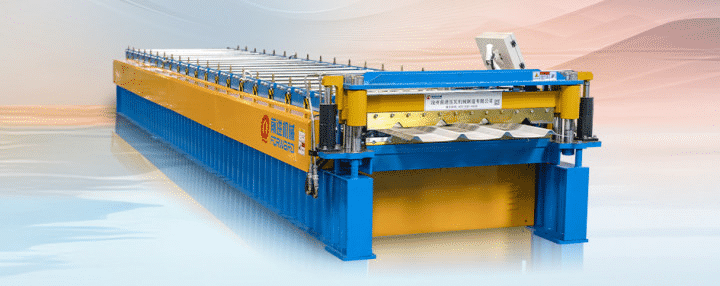

Cangzhou Forward Roll Forming Machinery has been at the forefront of these innovations, developing advanced roof and wall panel roll forming machines that incorporate cutting-edge control systems and automation features. The company’s focus on precision engineering and efficiency aligns perfectly with the industry’s direction toward smarter, more versatile equipment.

Market Trends and Growth Projections

The global roll forming machine market is projected to grow from USD 9.1 billion in 2024 to USD 12.2 billion by 2034, with a compound annual growth rate (CAGR) of 3%. This growth is primarily driven by expanding applications in the automotive, construction, and HVAC industries.

The construction sector remains a significant driver for roll forming machine demand, with increasing infrastructure development projects globally. Roll forming machines are extensively used to produce enclosures, wall and roofing panels, and structural shapes essential for resilient building construction.

Another notable trend is the growing emphasis on lightweight and durable materials in the automotive and construction sectors. Manufacturers are adopting roll-forming processes to enhance fuel efficiency and reduce emissions by achieving complex shapes using high-strength materials such as aluminum and advanced high-strength steel.

Roof and Wall Panel Machines: A Growing Segment

Roof and wall panel roll forming machines represent a particularly dynamic segment within the industry. These machines are essential tools in the construction and manufacturing sectors, producing high-quality metal panels for roofing and wall cladding.

The latest innovations in this segment include multi-profile capabilities, allowing a single machine to produce up to 16 different profiles with quick-change tooling systems. For example, the SSQ II MultiPro Roof Panel Machine features tooling that can be changed in 45 minutes or less with just one person and one wrench, significantly enhancing operational flexibility.

Cangzhou Forward Roll Forming Machinery specializes in this exact segment, offering advanced solutions for color steel roof/wall panel machines, glazed tile equipment, C/Z purlin machines, light steel keel machines, floor deck forming machines, and fully automatic cold roll forming equipment. The company’s expertise in this growing market segment positions it well to capitalize on increasing global demand.

Future Outlook: Sustainability and Customization

Looking ahead, the roll forming machine industry is increasingly focusing on sustainability and customization. The shift toward energy efficiency and green manufacturing is encouraging the acquisition of advanced roll-forming systems for producing environmentally friendly materials.

Customization is becoming a key differentiator, with manufacturers investing in research and development to improve machine capabilities, including faster changeover times, higher precision, and increased automation. This trend aligns perfectly with Cangzhou Forward’s commitment to developing specialized cold roll forming equipment tailored to specific customer requirements.

Conclusion

As the roll forming machine industry continues to evolve through technological innovation and market expansion, international exhibitions remain vital platforms for showcasing advancements and fostering business connections. Companies like Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd that stay at the forefront of these developments are well-positioned to meet the growing global demand for sophisticated metal forming solutions.

With continued investment in research and development, strategic partnerships, and a focus on customer-specific solutions, Cangzhou Forward exemplifies the industry’s direction toward smarter, more efficient, and more versatile roll forming machinery that meets the evolving needs of the construction, automotive, and manufacturing sectors worldwide.