This comprehensive guide explores the latest innovations in roof tile manufacturing equipment, highlighting the benefits of roof tiles in modern construction, market trends, and technological advancements that are reshaping the industry.

The Evolution of Roof Tile Technology in Modern Construction

Roof tiles have been a cornerstone of construction for centuries, but recent technological advancements in roof tiles\ manufacturing equipment have revolutionized this traditional building material. Today’s roof tile production systems combine ancient craftsmanship with cutting-edge technology, creating products that offer unparalleled durability, aesthetic appeal, and environmental benefits .

The global roof tile market is experiencing significant growth, with projections indicating an expansion from approximately $34 billion in 2024 to over $48 billion by 2032, representing a compound annual growth rate (CAGR) of 4.5-6.3%. This growth is driven by increasing construction activities, rising awareness of sustainable building practices, and technological innovations in manufacturing processes.

Advanced Roof Tile Roll Forming Machinery

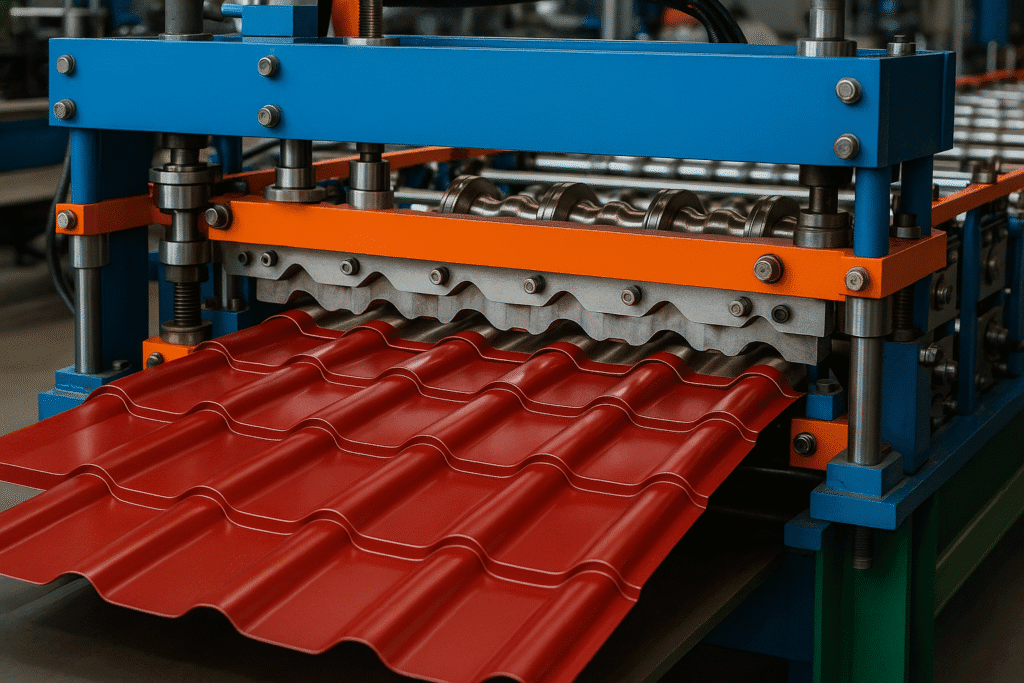

At the heart of modern roof tile production are sophisticated roll forming machines that have transformed manufacturing capabilities. These high-precision systems enable continuous production of various tile profiles with consistent quality and remarkable efficiency.

The latest roof tile roll forming machines feature:

- Automated step pressing systems with adjustable step length and depth

- Production speeds of 8-10 meters per minute

- Multi-patent certified designs meeting European quality standards

- Compatibility with various materials including color-coated steel and aluminum sheets

- Hydraulic cutting systems for precise finishing

Manufacturers like Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd are at the forefront of this technological revolution, developing equipment that balances production efficiency with product quality. Their machines incorporate individual standing column structures, advanced control systems from brands like MITSUBISHI and SIEMENS, and specialized step pressing units that create the distinctive profiles characteristic of premium roof tiles .

Double Layer Innovation: Maximizing Production Efficiency

One of the most significant advancements in roof tile manufacturing equipment is the development of double layer forming machines. These innovative systems can produce two different types of roofing profiles using a single production line, offering manufacturers unprecedented versatility and cost efficiency.

Double layer roof tiles machines can create combinations such as:

- Trapezoidal roofing sheets and corrugated roofing sheets

- Trapezoidal sheets and metal roof tiles

- Corrugated sheets and glazed roof tiles

While these machines cannot run both layers simultaneously due to PLC control limitations, they share a common motor with a clutch system that allows operators to switch between production modes. This design significantly reduces equipment footprint and capital investment while maximizing manufacturing capabilities.

The Compelling Benefits of Roof Tiles in Modern Construction

The surge in demand for roof tiles is driven by their numerous advantages over alternative roofing materials:

Exceptional Durability and Longevity

A properly installed roof tile system can last over 100 years, significantly outlasting most other roofing materials. Modern tiles can withstand extreme weather conditions including hail, high winds, and even fire, making them ideal for regions prone to severe climate events .

Aesthetic Appeal and Design Versatility

Today’s roof tiles are available in an extensive range of colors, textures, and profiles, allowing architects and homeowners to achieve distinctive aesthetic effects. From traditional Mediterranean styles to contemporary designs, roof tiles enhance curb appeal and architectural character.

Environmental Sustainability

Modern roof tiles manufacturing emphasizes sustainability, with many products made from natural, recyclable materials like clay and concrete. Their thermal mass helps regulate indoor temperatures, reducing energy consumption and supporting green building initiatives .

Low Maintenance Requirements

Unlike many roofing alternatives, roof tiles require minimal maintenance over their lifespan. Their durability and resistance to common issues like rot, insect damage, and color fading translate to lower long-term ownership costs despite higher initial installation expenses .

Market Trends Driving Innovation in Roof Tile Equipment

Several key trends are shaping the evolution of roof tiles manufacturing technology:

Integration of Solar Technology

In 2023, major manufacturers like Wienerberger launched innovative solar roof tiles that seamlessly integrate photovoltaic technology with traditional roofing aesthetics. This convergence of energy generation and building protection represents a significant advancement in sustainable construction .

Focus on Lightweight Solutions

Manufacturers are developing lighter roof tiles options that maintain durability while reducing structural load requirements. These innovations make roof tiles viable for a broader range of building types and renovation projects 5 .

Emphasis on Energy Efficiency

Modern roof tile designs increasingly incorporate features that enhance energy efficiency, such as improved insulation properties and reflective surfaces that reduce cooling costs in hot climates .

Regional Market Expansion

While Europe remains the largest market for roof tiles , the Asia-Pacific region is experiencing the fastest growth, driven by rapid urbanization and construction activity in countries like China and India. This geographic shift is influencing equipment design to accommodate different regional preferences and building codes .

Challenges and Considerations

Despite their many advantages, roof tile systems present certain challenges that manufacturers and installers must address:

- Higher initial cost compared to some alternative roofing materials

- Greater weight requiring adequate structural support

- More complex installation requiring specialized expertise

- Potential for individual tile breakage during installation or from heavy impact

Equipment manufacturers like Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd are addressing these challenges through innovations in material formulation, production techniques, and installation systems that enhance performance while reducing costs.

Conclusion: The Future of Roof Tile Manufacturing

As the global construction industry increasingly prioritizes sustainability, durability, and aesthetic appeal, roof tiles are positioned for continued growth and innovation. Advanced manufacturing equipment from companies like Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd is enabling the production of higher-quality, more versatile, and increasingly cost-effective roof tile solutions.

The integration of digital technologies, automation, and sustainable practices in roof tile manufacturing represents not just an evolution of traditional building materials, but a revolution in how we approach roofing systems for the 21st century. For construction professionals, building owners, and homeowners alike, these advancements offer exciting possibilities for creating structures that are both beautiful and built to last.

Recommended Outbound Links

- Metal Construction News – For current trends in metal roofing industry

- Machinery Trader – For information on available roof tile manufacturing equipment

- Thomas Net – For comprehensive information on roofing materials

- Global Spec – For technical specifications on roofing materials

- Construction Equipment Guide – For the latest in construction equipment technology