The aerial work platform (AWP) industry is experiencing a remarkable transformation, driven by technological innovation, sustainability demands, and evolving safety standards. At the heart of this revolution is an often-overlooked manufacturing process: roll forming. As the global AWP market surges toward USD 20.47 billion by 2032 with a robust 7.9% CAGR, manufacturers are turning to advanced roll forming machines to create the next generation of scissor lifts and boom lifts that meet increasingly stringent environmental and performance requirements.

The Electric AWP Revolution

The most significant trend reshaping the aerial work platform landscape is electrification. Electric AWPs are rapidly gaining market share, particularly in urban environments and indoor applications where zero emissions and low noise operation are essential. This shift is driven by several factors:

- Environmental Regulations : Governments worldwide are implementing stricter emission standards, accelerating the transition to electric equipment.

- Sustainability Goals : Construction companies and rental fleets are increasingly prioritizing carbon footprint reduction.

- Operational Advantages : Electric AWPs offer lower operating costs, reduced maintenance, and quieter operation.

- Technological Advancements : Improvements in battery technology have extended operating times and reduced charging cycles.

The global electric aerial work platform market alone is projected to grow from USD 12 billion in 2023 to approximately USD 26 billion by 2032, representing a 9.2% CAGR.

Roll Forming: The Manufacturing Backbone of Modern AWPs

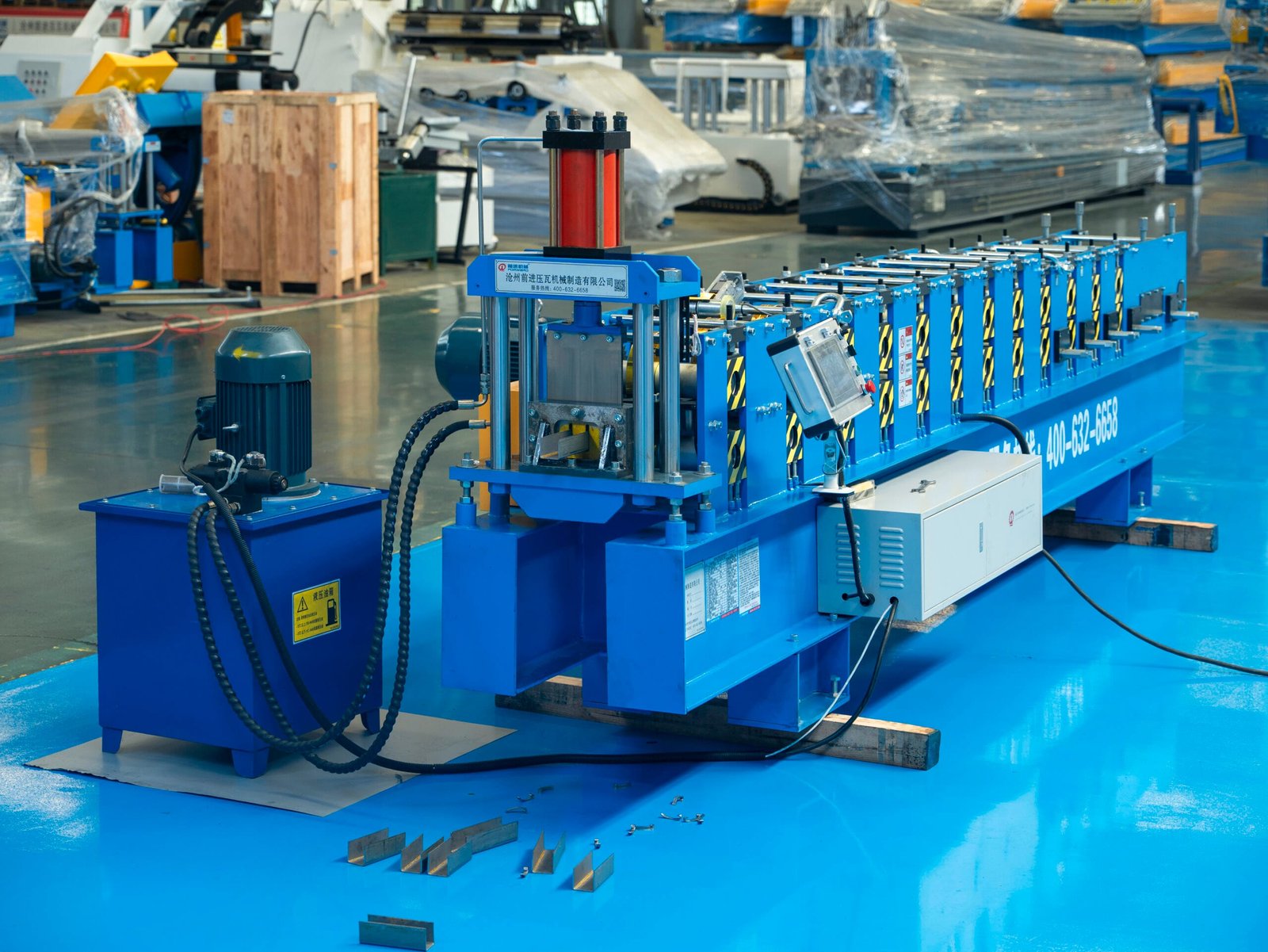

Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd has been at the forefront of this transformation, providing specialized roll forming equipment that enables AWP manufacturers to produce critical structural components with precision, consistency, and efficiency. The company’s decade-long experience in designing and manufacturing pressure equipment has positioned it as a key supplier to the aerial work platform industry.

Roll forming machines are instrumental in manufacturing several critical components of aerial work platforms:

- Chassis Frames : The foundation of any AWP, providing structural integrity and stability. Roll forming allows for the creation of high-strength, lightweight frames that can support heavy loads while minimizing overall weight.

- Scissor Arms : In scissor lifts, the extending arms must maintain precise tolerances and structural integrity. Roll forming creates consistent, strong components that ensure smooth operation and safety.

- Boom Structures : For articulating and telescopic boom lifts, roll-formed components provide the necessary strength-to-weight ratio for extended reach capabilities.

- Platform Decks : Roll forming produces the structural elements of work platforms, ensuring they can safely support workers and equipment at height.

- Outrigger Components : Critical safety elements that prevent tip-overs, manufactured with high precision using roll forming technology.

Sustainability Benefits of Advanced Roll Forming in AWP Manufacturing

The integration of modern roll forming technology into aerial work platform manufacturing delivers significant sustainability benefits:

- Material Efficiency : Advanced roll forming machines minimize material waste through precise forming processes, reducing the environmental impact of manufacturing.

- Weight Reduction : Roll forming enables the creation of high-strength components with optimized material usage, resulting in lighter AWPs that require less energy to operate and transport.

- Enhanced Durability : Precisely formed components have better structural integrity, extending the service life of aerial work platforms and reducing resource consumption over time.

- Support for Electric Designs : The weight savings achieved through roll forming are particularly valuable for electric AWPs, where battery range is directly impacted by overall weight.

- Manufacturing Efficiency : Modern roll forming processes consume less energy than traditional manufacturing methods, further reducing the carbon footprint of AWP production.

Market Trends Driving Innovation

Several key market trends are accelerating the adoption of advanced roll forming technology in aerial work platform manufacturing:

- Growing Demand for Electric AWPs : The market for electric scissor lifts and boom lifts is expanding rapidly, with manufacturers introducing new models to meet sustainability requirements. For example, JCB recently unveiled two flexible boom aerial work platforms, the A45E and A45EH, offering diesel/electric hybrid and battery-electric drivelines.

- Height Innovation : The industry is seeing increased demand for AWPs with greater working heights and reach capabilities, requiring stronger yet lighter structural components that can only be achieved through advanced forming processes.

- Safety Enhancements : Improved stability systems, load-sensing technologies, and structural reinforcements are being integrated into new AWP designs, all requiring precisely formed components.

- Compact Design Trends : Urban construction and indoor applications are driving demand for more compact and maneuverable AWPs that maintain full functionality, challenging manufacturers to optimize component design.

The Future of AWP Manufacturing

Looking ahead, the integration of roll forming technology with other advanced manufacturing processes will continue to transform aerial work platform production:

- Digital Integration : Roll forming machines are increasingly incorporating IoT sensors and digital controls, enabling real-time quality monitoring and predictive maintenance.

- Customization Capabilities : Flexible roll forming systems allow manufacturers to quickly adapt production for different AWP models and specialized applications.

- Hybrid Materials : Advanced roll forming techniques are enabling the use of high-strength steel alloys and composite materials in AWP components, further improving performance and sustainability.

- Localized Production : Portable roll forming systems are making it possible to manufacture AWP components closer to assembly facilities, reducing transportation emissions and costs.

Conclusion

As the aerial work platform industry continues its rapid evolution toward more sustainable, efficient, and capable equipment, roll forming technology will remain a critical enabler of innovation. Companies like Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd are playing an essential role in this transformation, providing the specialized manufacturing equipment needed to produce the next generation of aerial work platforms.

The synergy between advanced roll forming capabilities and electric AWP design is creating unprecedented opportunities for sustainability improvements in construction and maintenance operations worldwide. With the global market for aerial work platforms projected to reach USD 37.74 billion by 2033, the importance of efficient, precise manufacturing processes will only continue to grow. 1

For construction companies, rental fleet operators, and facility managers looking to maximize efficiency while minimizing environmental impact, understanding the manufacturing technology behind modern aerial work platforms provides valuable insight into the quality, performance, and sustainability benefits of today’s equipment.