The Role of Roll Forming Machines in Cold-Formed Steel Production

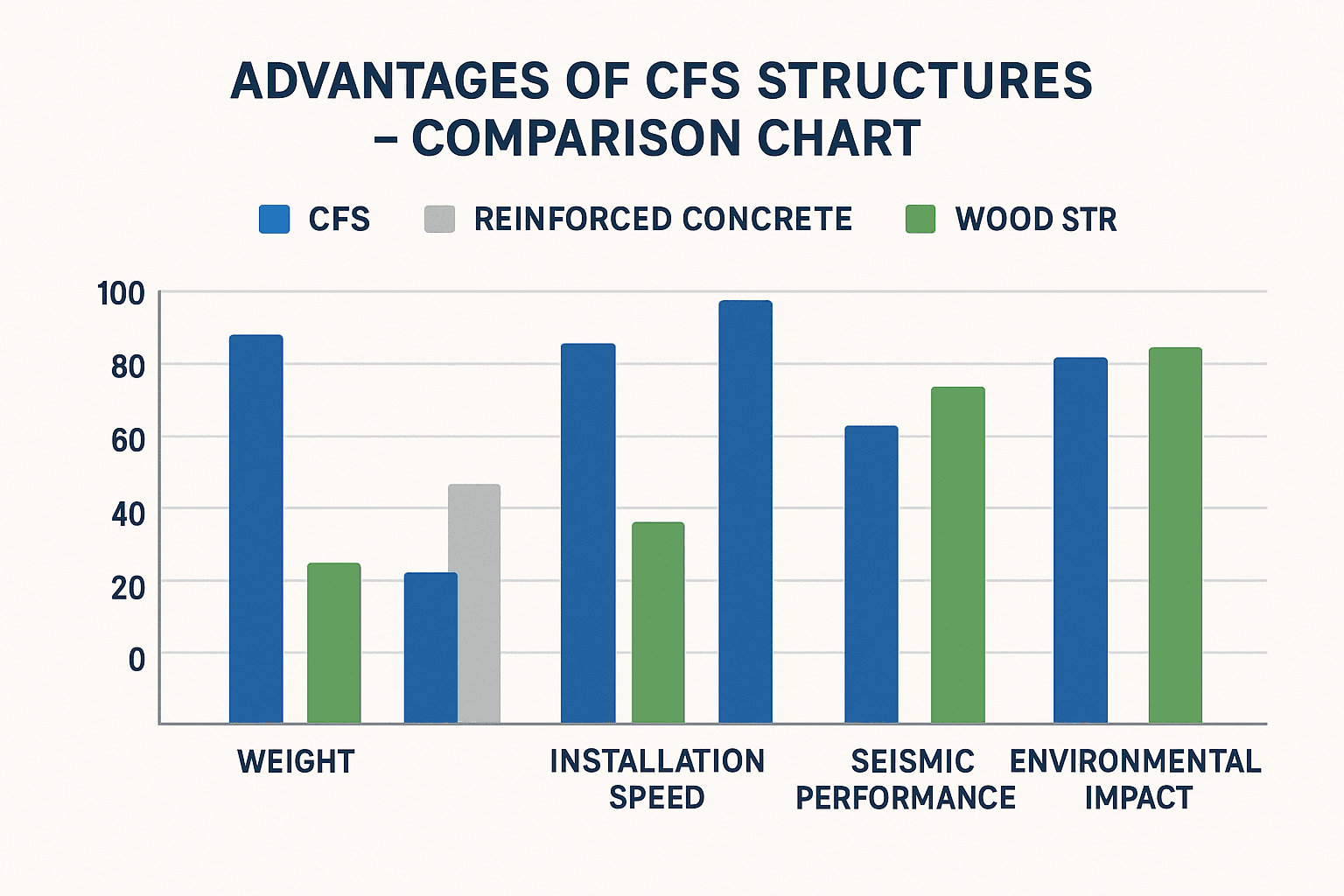

Cold-formed steel (CFS) has become a crucial material in modern construction, offering numerous advantages over traditional materials like reinforced concrete and wood. The roll forming machine is key to the efficient production of CFS, providing precise shaping and strength. With its lightweight, fast installation, and seismic resistance, CFS is increasingly used in residential, commercial, and industrial buildings. This innovation is especially significant in the context of sustainable and eco-friendly construction practices.

Learn more about the roll forming machine process at-https://www.steel.org/

As the construction industry increasingly moves towards green technologies, particularly under the global push towards carbon neutrality, CFS is expected to see greater adoption. Below, we highlight the key advancements in cold-formed steel applications, component design, and seismic performance.

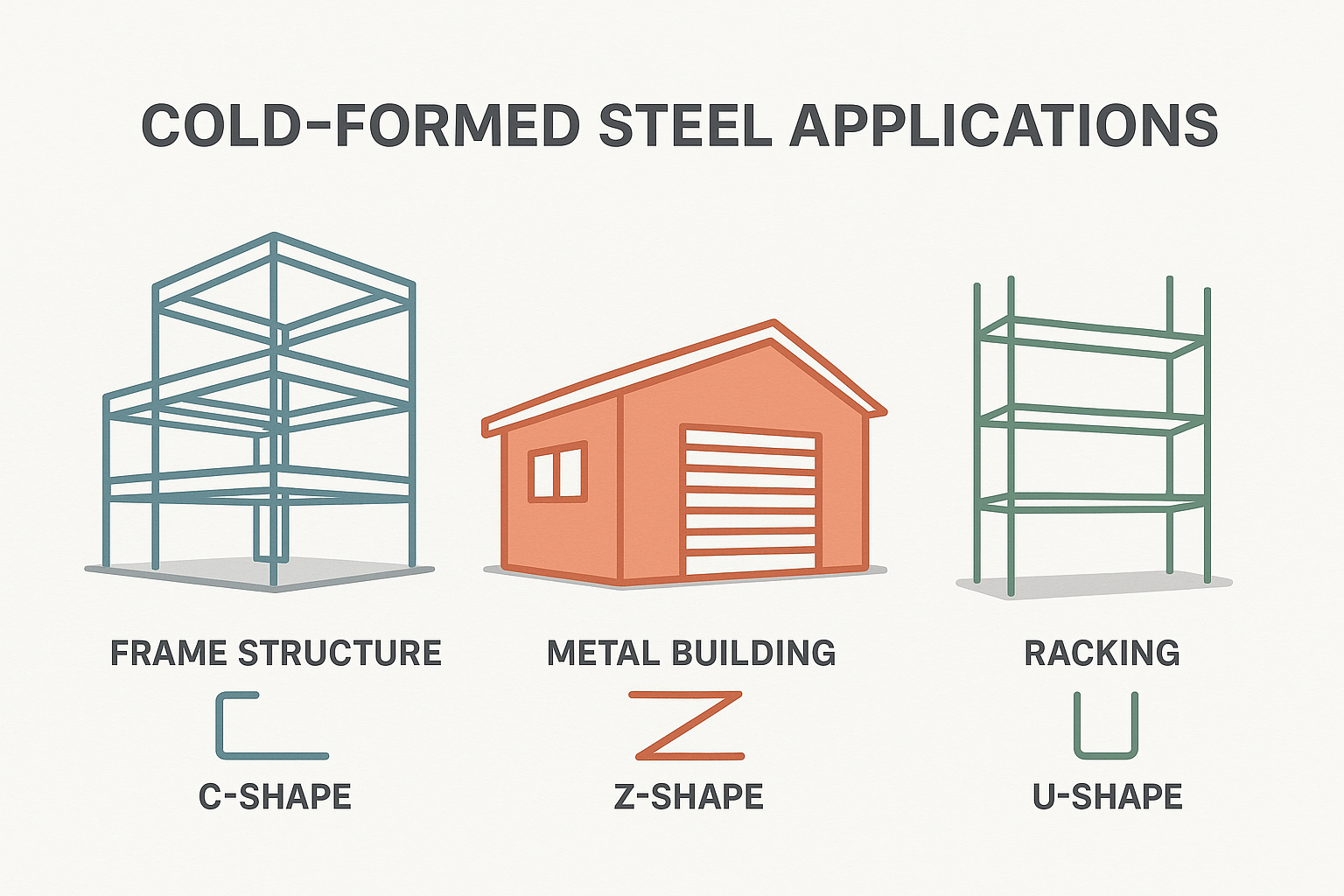

Key Applications of Cold-Formed Steel (CFS)

CFS is widely used in the following construction areas:

- Frames: While traditionally used in low-rise buildings, CFS frames are now being employed in mid- and high-rise structures as well, even in seismic zones. In North America, a comprehensive set of CFS frame standards has been developed, enabling its wider adoption.

- Metal Structures: CFS components are increasingly used in secondary systems such as purlins, wall panels, and thin plates. These systems are not only cost-effective but also perform well in both residential and industrial settings.

- Shelving Systems: CFS has revolutionized shelving systems with high-efficiency designs that use innovative profiles and connections. These systems are highly durable, reducing the need for regular maintenance.

Cold-Formed Steel Components

CFS components such as C-shaped, Z-shaped, and custom « hat » sections are commonly used in framing and shelving systems. Recent advances have pushed the boundaries of traditional profiles, incorporating new manufacturing technologies that allow for lighter, stronger, and more sustainable structures.

One of the most significant innovations is the LiteSteel Beam design, which combines the advantages of cold-formed and hot-rolled steel for superior strength and torsional stiffness. This new section type is making its mark in both the CFS framing and shelving markets, offering enhanced fire resistance, thermal insulation, and soundproofing.

Advanced Analysis Techniques

The design and analysis of CFS components present unique challenges. While traditional structural analysis methods often use linear models, the development of advanced techniques such as Generalized Beam Theory (GBT) has allowed engineers to better simulate and predict the behavior of CFS structures under various loading conditions, including seismic forces. This makes CFS an even more attractive option for large-scale projects.

GMNIA (Geometrically and Materially Nonlinear Analysis) is a powerful tool that can simulate complex behaviors in thin-walled structures, like CFS, where traditional analysis methods may fall short.

CFS Seismic Design

Seismic performance is a key factor in the design of CFS structures, particularly for regions prone to earthquakes. Recent research has focused on nonlinear time-history analysis, allowing for more accurate predictions of how CFS structures will behave under seismic loading. CFS shear walls, in particular, have seen significant testing and development, with improvements aimed at enhancing energy dissipation through innovative systems like fusible links.

Conclusion: The Future of Cold-Formed Steel in Construction

Cold-formed steel is an incredibly versatile material that continues to evolve. Its applications in building frames, metal structures, and shelving systems are expanding, and advancements in analysis and design methods have made it an even more viable option for a variety of construction projects. As the industry moves toward more sustainable and cost-effective solutions, CFS will remain at the forefront of modern construction technologies.

At Forward Global, we are committed to offering top-of-the-line roll forming machines that produce high-quality cold-formed steel components. Our metal roll forming machines are designed for efficiency, durability, and precision, helping you achieve optimal results for your construction projects.