Advanced Roll Forming Machine Technology: Components, Maintenance and Industry Applications

In today’s competitive manufacturing landscape, precision metal forming is critical for industries ranging from construction to automotive. The roll forming machine stands as a cornerstone technology that enables high-volume production of consistent metal profiles with remarkable efficiency. As manufacturers seek to optimize their operations, understanding the intricacies of modern roll forming equipment becomes essential for making informed investment decisions and maintaining peak operational performance.

The Fundamental Working Principles of Roll Forming Machines

At its core, a roll forming machine facilitates a multi-station metalworking process designed to progressively bend and shape sheet metal into precise, repeatable profiles. Unlike traditional press braking methods, roll forming offers a continuous operation that transforms flat metal coils into complex shapes through a series of carefully calibrated roller stations.

The Roll Forming Process Explained

The process begins when sheet metal, typically from a coil, enters the machine through a decoiler and straightener. As the material advances through the roll forming equipment, each set of rollers gradually bends the metal closer to its final shape. This progressive forming approach minimizes material stress and ensures consistent quality even at high production speeds.

What makes metal roll forming machines particularly valuable is their ability to handle long production runs with minimal setup changes. The continuous nature of the process enables manufacturers to achieve high throughput rates while maintaining tight tolerances, making them ideal for applications requiring both precision and volume.

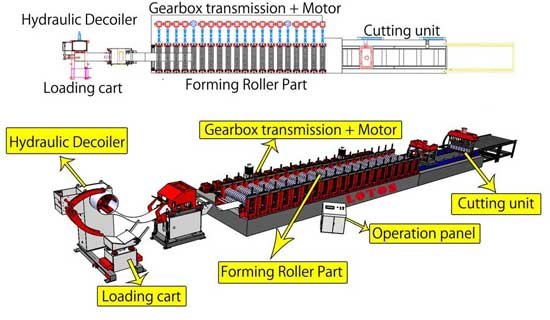

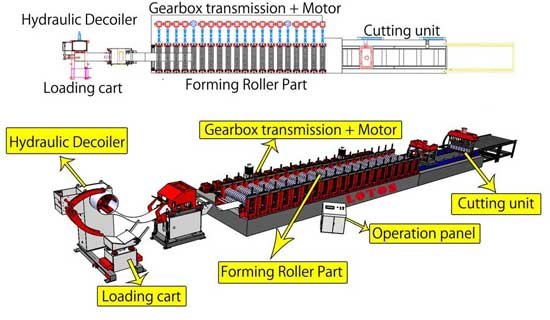

Essential Components of Modern Roll Forming Machines

Understanding the key components of a roll forming machine helps operators maintain optimal performance and troubleshoot potential issues before they affect production quality.

Entry System Components

The entry system typically includes:

- Decoiler – Holds and unwinds metal coil for continuous feeding

- Straightener – Removes coil memory and flattens material

- Entry guides – Align material properly before it enters forming stations

Forming Station Components

The heart of any cold roll forming machine lies in its forming stations, which include:

- Forming rolls – Precision-engineered tooling that progressively shapes the material

- Shafts – Support and drive the forming rolls

- Spacers – Maintain proper alignment between forming rolls

- Bearings – Enable smooth rotation of rolls and shafts

- Gearboxes – Transfer power from motors to forming stations

Cutting and Output Components

After forming, the material undergoes:

- Cutoff press – Shears formed profile to desired length

- Punching stations – Create holes, slots or other features (if applicable)

- Exit table – Supports finished products

- Stacking system – Collects and organizes completed parts

Understanding how these components work together is crucial for anyone operating or maintaining a roof roll forming machine or other specialized forming equipment.

Latest Technological Advances in Roll Forming Equipment

The evolution of roll forming machine technology continues to accelerate, with several key innovations enhancing productivity, flexibility, and quality control.

Automated Control Systems

Modern roll forming equipment now incorporates sophisticated control systems that offer:

- Precision servo drives for exact positioning

- Real-time monitoring of critical parameters

- Automated tool adjustment for different profiles

- Integration with factory management systems

These advancements allow operators to switch between different profiles more efficiently, reducing downtime and increasing production flexibility—a critical advantage in today’s just-in-time manufacturing environment.

Enhanced Material Handling Capability

The latest generation of metal roll forming machines can process an expanding range of materials, including:

- High-strength steels

- Lightweight aluminum alloys

- Pre-painted and pre-finished materials

- Composite materials

This versatility opens new application possibilities across industries, from automotive lightweight components to sophisticated architectural elements.

Improved Quality Assurance Technologies

Quality control has been revolutionized in modern roll forming machine systems through:

- Inline dimensional scanning

- Integrated vision systems for defect detection

- Real-time performance analytics

- Predictive maintenance algorithms

These technologies allow manufacturers to identify and address potential issues before they affect product quality, dramatically reducing scrap rates and improving overall operational efficiency.

Essential Maintenance Practices for Roll Forming Machines

Proper maintenance is critical to extending the service life and ensuring the consistent performance of any roll forming machine. A structured maintenance program should include daily, weekly, and monthly tasks.

Daily Maintenance Requirements

Operators should perform these tasks daily to keep the roll forming equipment running smoothly:

- Cleaning – Remove metal debris, dust, and other contaminants from the machine surface and interior components

- Lubrication check – Ensure all moving parts have adequate lubrication

- Visual inspection – Check for any obvious signs of wear, damage, or misalignment

- Tightening loose components – Verify that bolts and fasteners remain secure

Weekly Maintenance Procedures

Once per week, more comprehensive maintenance should include:

- Thorough cleaning – Deep clean the rollers, guides, and moving parts

- Lubrication of all moving parts – Apply fresh lubricant to rollers, guides, and chains

- Electrical system inspection – Check for any loose wires or damaged cables

- Belt and pulley inspection – Examine for wear and proper tension

- Alignment verification – Ensure all components remain properly aligned

Monthly Maintenance Tasks

Monthly maintenance for cold roll forming machines should focus on system-wide checks:

- Worn parts identification – Inspect rollers, guides, chains, and bearings for wear

- Filter replacement – Check and replace air and oil filters as needed

- Hydraulic system inspection – Look for leaks, damage, or wear

- Pneumatic system check – Verify proper function without leaks

- Calibration verification – Confirm the machine produces correct profiles and dimensions

Following these maintenance protocols can significantly reduce downtime and extend equipment life, making them essential knowledge for anyone operating roll forming equipment.

Roll Forming vs. Press Braking: Choosing the Right Technology

When evaluating metal forming options, manufacturers often compare roll forming machines with press braking technology. Each approach offers distinct advantages depending on production requirements.

Advantages of Roll Forming

Roll forming machines excel in these scenarios:

- High-volume production – Continuous operation enables greater throughput

- Long parts – Handles extended lengths with consistent quality

- Complex profiles – Creates sophisticated shapes through progressive forming

- Material efficiency – Minimizes waste and optimizes material utilization

- Consistent quality – Maintains tight tolerances over extended production runs

When Press Braking May Be Preferred

Press braking remains advantageous in certain situations:

- Short production runs – Lower setup costs for small batches

- Simple bends – More economical for basic profiles with few bends

- Flexible production – Easier tool changes between different parts

- Lower initial investment – Generally lower equipment cost for entry-level capacity

Understanding these differences helps manufacturers select the optimal technology for their specific production needs. For many growing operations, investing in a versatile roll forming machine provides long-term advantages as production volumes increase.

Industry Applications and Success Stories

The versatility of modern roll forming machines has led to their adoption across diverse industries, each leveraging the technology’s unique capabilities to address specific challenges.

Construction Industry Applications

In construction, roof panel roll forming machines produce essential components including:

- Metal roofing panels

- Wall cladding systems

- Structural framing members

- Ceiling grid components

- Floor deck profiles

These applications benefit from roll forming’s ability to produce consistent, high-quality components at the volumes required for commercial construction projects.

Automotive Sector Implementation

The automotive industry leverages metal roll forming machines for:

- Structural reinforcements

- Door frames and components

- Chassis elements

- Seat frames and tracks

- Safety systems

The precision and strength of roll-formed parts make them ideal for safety-critical automotive applications where consistent performance is non-negotiable.

Case Study: Efficiency Improvements

[Example Company] recently upgraded their production line with a modern roll forming machine, resulting in:

- 35% increase in production throughput

- 28% reduction in material waste

- 42% decrease in setup times between production runs

- Significant quality improvements with reject rates below 0.5%

These impressive results demonstrate the potential return on investment when upgrading to current roll forming equipment technology.

Selecting the Right Roll Forming Machine for Your Requirements

Choosing the optimal roll forming machine requires careful evaluation of several key factors to ensure the equipment aligns with production needs and business objectives.

Production Volume Considerations

Assess your production requirements:

- Annual production volume

- Typical batch sizes

- Peak production periods

- Growth projections

Higher volumes typically justify more sophisticated roll forming equipment with greater automation and higher throughput capability.

Material Specifications

Different roll forming machines are optimized for specific materials:

- Material types (steel, aluminum, copper, etc.)

- Thickness range capabilities

- Width capabilities

- Surface finish considerations (pre-painted, galvanized, etc.)

Ensure the selected machine can handle your full range of material specifications with appropriate quality.

Profile Complexity Analysis

The complexity of your required profiles impacts machine selection:

- Number of bends required

- Tightest radius requirements

- Dimensional tolerance needs

- Special features (holes, cutouts, etc.)

More complex profiles may require additional forming stations or specialized tooling in your roll forming machine configuration.

Budget and ROI Calculations

Financial considerations should include:

- Initial equipment investment

- Installation and training costs

- Ongoing maintenance expenses

- Expected productivity improvements

- Quality enhancement value

- Energy efficiency gains

A comprehensive ROI analysis helps justify the investment in advanced roll forming equipment by quantifying both direct and indirect benefits.

Conclusion: Maximizing the Value of Your Roll Forming Equipment

The roll forming machine represents a significant but worthwhile investment for manufacturers seeking consistent quality, high productivity, and operational efficiency. By understanding the fundamentals of roll forming technology, implementing proper maintenance practices, and selecting equipment tailored to specific production requirements, companies can achieve substantial competitive advantages.

As technology continues to evolve, staying informed about the latest roll forming machine innovations helps manufacturers maintain their edge in increasingly competitive markets. Whether producing construction materials, automotive components, or specialized industrial profiles, the versatility and efficiency of modern roll forming equipment make it an essential technology for metal forming operations worldwide.

For companies considering an investment in new metal roll forming machines or upgrading existing equipment, consulting with experienced industry experts can provide valuable insights into optimal configurations and implementation strategies to maximize return on investment and long-term operational success.

Recommended external resources for further reading:

- The Fabricator – Leading resource for metal forming and fabricating information

- American Iron and Steel Institute – Industry standards and research on steel applications

- Metalforming Magazine – Latest trends and technologies in metal forming

- International Journal of Machine Tools and Manufacture – Academic research on manufacturing technologies

For personalized consultation on selecting the optimal roll forming solution for your specific production requirements, contact our team of specialists at Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd.