The global roll forming machine market is experiencing steady growth, with recent market analysis projecting expansion from $9.1 billion in 2024 to $12.2 billion by 2034, representing a compound annual growth rate (CAGR) of 3% 1 . This growth trajectory highlights the increasing importance of roll forming technology across various industrial sectors, particularly in automotive manufacturing, construction, and infrastructure development.

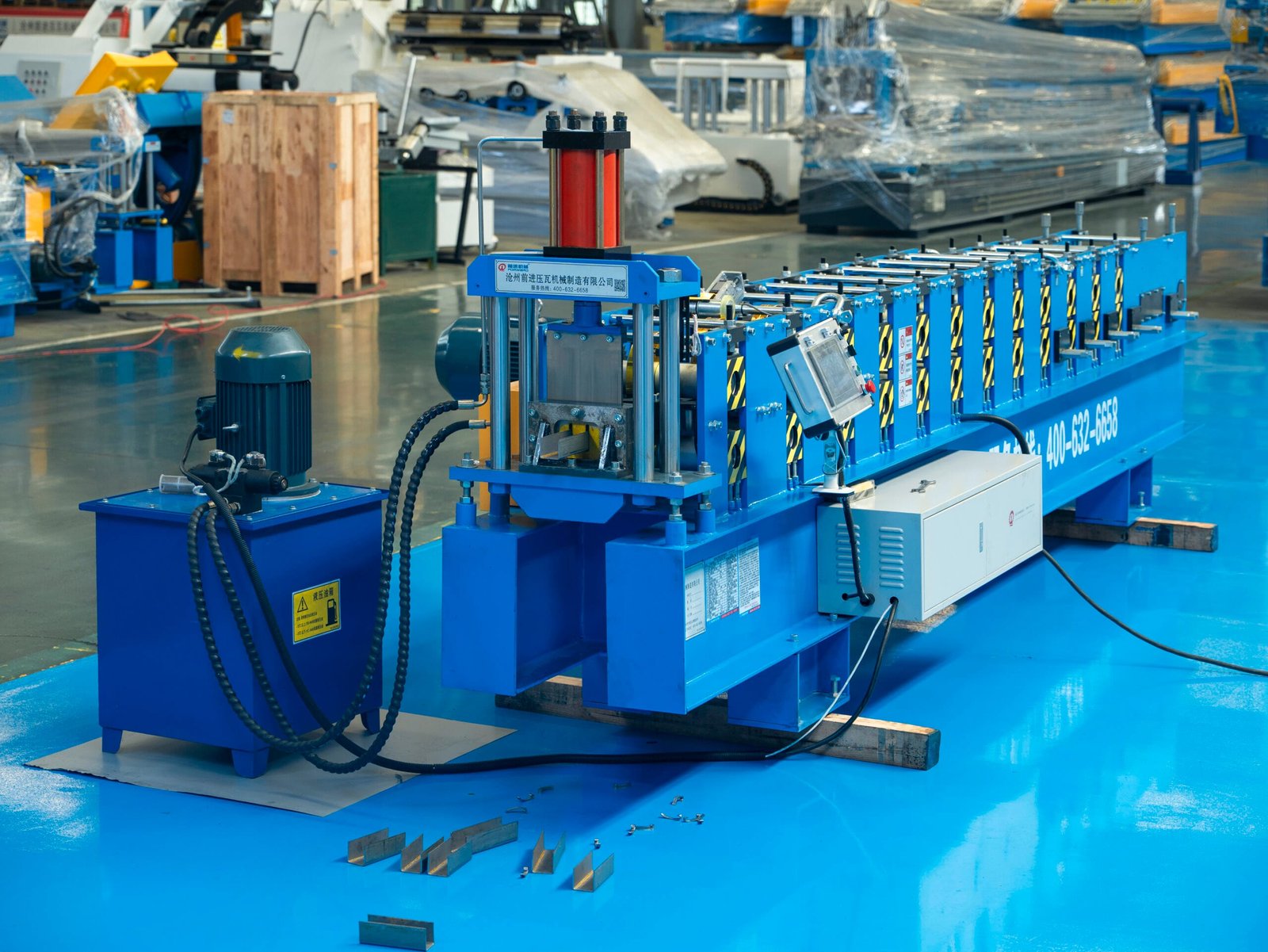

As a leading manufacturer in the industry, Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd has been at the forefront of this market evolution, specializing in cold roll forming equipment and automated production lines. The company’s expertise in developing high-quality machines for metal roofing, wall panels, glazed tile equipment, C/Z purlin machines, light steel keel machines, floor deck forming machines, and fully automatic cold roll forming equipment positions it perfectly to capitalize on these emerging market trends.

Five Key Growth Drivers Transforming the Roll Forming Machine Industry

1.Rising Demand for Lightweight Materials in Automotive Manufacturing

The automotive sector has emerged as a significant driver for the roll forming machine market, accounting for approximately 36.1% of market share in 2025. Manufacturers are increasingly adopting roll forming processes to enhance fuel efficiency and reduce emissions in vehicles. These processes enable the creation of complex shapes using high-strength materials such as aluminum and advanced high-strength steel.

Roll-formed parts are extensively utilized in vehicle chassis and body structures, prompting the development of advanced roll forming equipment specifically designed for these high-strength materials. This trend aligns perfectly with Cangzhou Forward Roll Forming Machinery ‘s focus on innovation and precision engineering in their machine designs.

2.Construction Sector Expansion Driving Market Growth

The construction industry remains a primary consumer of roll forming machines , with applications spanning from structural components to roofing and wall panels. The ongoing infrastructure development projects globally, particularly in emerging economies, have significantly boosted demand for these machines.

Roll forming is widely adopted in construction applications such as rails, pipes, and panels due to its ability to produce long, accurately shaped sections with high output. The roof roll forming machine segment, in particular, has seen substantial growth as modern construction projects increasingly require customized, durable roofing solutions.

3.Technological Advancements Enhancing Machine Capabilities

Industry 4.0 technologies, including IoT and AI, are revolutionizing production processes in the roll forming sector. Leading companies are implementing smart roll forming machines equipped with real-time monitoring systems for predictive maintenance and reduced downtime.

The automatic roll forming machines segment is expected to contribute 45.8% share of the market in 2025, driven by continuous innovations making the process more efficient. These machines minimize human intervention and offer precision, consistency, and higher production output compared to manual machines.

4.Growing Demand in Defense and Aerospace Sectors

The defense and aerospace sectors are increasingly utilizing roll forming machines due to their need for lightweight yet strong materials and composites that can withstand rigorous environments. Military and aerospace manufacturers are emphasizing weight reduction in components to increase performance and fuel efficiency, making roll forming processes essential.

Roll-formed components made of aluminum and titanium are finding applications in aircraft structures and military vehicles, requiring precision and resilience that only advanced metal roll forming machines can provide.

5.Regional Market Expansion and Opportunities

The Asia Pacific region leads the roll forming machine market, capturing approximately 31.1% share in 2025. This dominance is attributed to rapid industrialization, particularly in countries like China and India, extensive infrastructure development, and manufacturing activities.

Meanwhile, North America exhibits strong growth with 23.2% share of the market in 2025, led by countries like the U.S. and Canada. This growth is credited to increasing investments in infrastructure projects and advancements in manufacturing technologies.

Upcoming Industry Exhibitions for Roll Forming Machine Manufacturers and Buyers

Industry exhibitions provide excellent opportunities for manufacturers like Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd to showcase their latest innovations and for potential buyers to explore cutting-edge technologies. Several significant exhibitions are scheduled for the coming years:

- Metal Forming Expo 2026 — Scheduled for April 24-26, 2026, at Pune International Exhibition and Convention Centre (PIECC) in India. This exhibition will feature 175+ suppliers of metal forming, sheet metal working & manufacturing technologies.

- EMO Hannover 2025 — One of the world’s leading trade fairs for production technology, focusing on cutting and forming machine tools, automated material flow, and industrial electronics.

- LAMIERA 2025 — Taking place from May 6-9, 2025, at fieramilano Rho in Italy. This is the only exhibition event in Italy dedicated exclusively to the industry of machine tools for sheet metal forming and cutting.

- FABTECH Chicago 2025 — A premier event for the metal forming, fabricating, welding, and finishing industries in North America.

Conclusion

The roll forming machine market is poised for significant growth over the next decade, driven by technological advancements, expanding applications across various industries, and increasing demand for precision-engineered metal components. As a leading manufacturer in this space, Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd is well-positioned to meet the evolving needs of customers worldwide with its comprehensive range of high-quality roll forming equipment .

For manufacturers and buyers looking to stay ahead in this dynamic market, keeping abreast of the latest trends and participating in industry exhibitions will be crucial for success. The future of roll forming technology promises even greater innovation, efficiency, and application versatility as the market continues its upward trajectory toward the projected $12.2 billion valuation by 2034.